Major Announcement

Rovtech Acquires VALOR ROV Business from Seatronics

We recently announced a transformative seven-figure deal to acquire the

VALOR

Remotely Operated Vehicle (ROV) business from Seatronics Ltd.

This strategic acquisition doubles our workforce across #Aberdeen and

#Cumbria and will enhance our position as a global technology leader

in

manufacturing robotics, tooling and harsh environment equipment for nuclear

and

subsea operations.

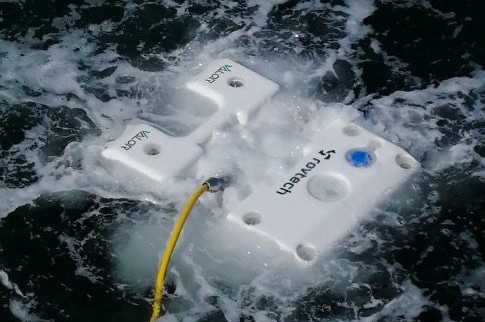

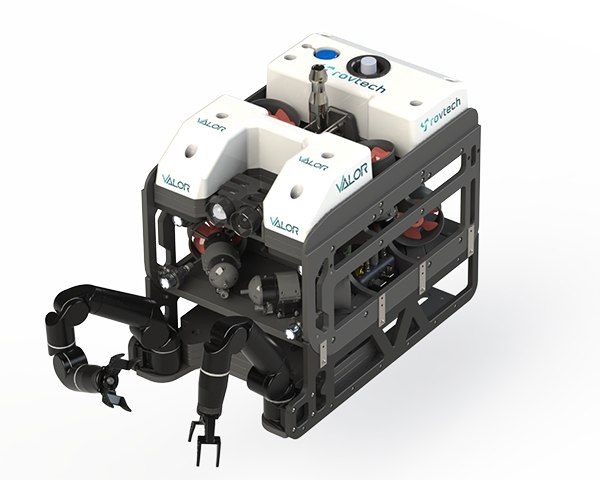

The VALOR ROV, known for its lightweight design and powerful capabilities, will enhance our portfolio with cutting-edge technology that redefines industry standards in subsea operations.

“The VALOR ROV has provided a step change in what has traditionally been the limitations of an Observation Class ROV. Its lightweight design, power, manoeuvrability, and unmatched ability to integrate several state-of-the-art sensors, makes it an indispensable tool for modern subsea operations, and we are thrilled to integrate this business into Rovtech.”

– John Polson, CEO

The deal follows our acquisition by Ventex Studio, which is investing in climate-focused innovations and supporting companies driving change in energy transition. Together, we’re going to push the boundaries of robotics and explore new horizons.

Read the full press release here

Download Data SheetVALOR ROV Specifications

| Depth Rating | 300m (1000 ft.) |

| Length | 860mm (33.9 in) |

| Width | 600mm (23.6 in) |

| Height | 565mm (22.2 in) |

| Weight in Air Max Payload Through Frame Lift | ~ 105Kg (231.5 lbs) Up to 21kg (46 lbs) 100kg (220 lbs) |

| System Input Voltage | Two ranges of PSU - 415VAC (373-456 VAC) and 480VAC (432-528 VAC) |

| System Input Current | 20 A – Base System |

| Power Delivered to ROV | 640V DC nominal, 10kW Base System |

| Tether (300m supplied) 1 | 6 x Power Conductors, 6 x SM Fibre, 1x Shielded Twisted Pair |

| Topside Weight | 90kg (198 lbs) |

| Display | 1 x 17.3” Rackmount HD Monitor, 1 x Rackmount HD Touchscreen Monitor |

| Transit Case | 417mm (H) x 583mm (W) x 870mm (D) |

| Input Device | Joystick and throttle controller |

| Number of Horizontal Thrusters | 4 (vectored at 43°) |

| Type of Horizontal Thrusters | RS485 controlled Brushless DC |

| Number of Vertical Thrusters | 2 (angled at 30°) |

| Type of Vertical Thrusters | RS485 controlled Brushless DC |

| Thrust Forward/Backward/Lateral | 80kgf |

| Thrust Vertical | 50kgf |

| Number of Lights | 4 |

| Type of Lights | 2250 Lumen dimmable LED |

| Number of Cameras Supplied | 2 x GigE Cameras |

| Additional Cameras Supported | 1 x pal SC, 1 HD i camera, up to 5 IP cameras |

| Expansion Ports | 5 x User connectors 2 (12V-48V DC, Gigabit Ethernet, RS232/422/RS485, 1 PPS, 1 x 640V high-power, optional 8th thruster port) |

| Pilot Aids | Auto Heading, Auto Depth, Auto Altitude (with DVL/Altimeter), Auto Hover 3, Advanced Navigation Spatial Gyro (INS), Mission planning, Waypoint following, Optional remote piloting |

- 300m recommended for optimum performance

- 3A maximum current per port

- Adequate for pilot to take hands off the controls for short durations

Harsh environment manufacturing for when failure isn’t an option

Precision ROVs, monitoring and intervention systems designed to operate in the world's harshest environments, including deep ocean, extreme heat and nuclear. Look out for our new site launching soon, you can access our current site via the link below.